Training Stress Analysis Caesar II

Caesar II

Rp4000000.00

DESCRIPTION

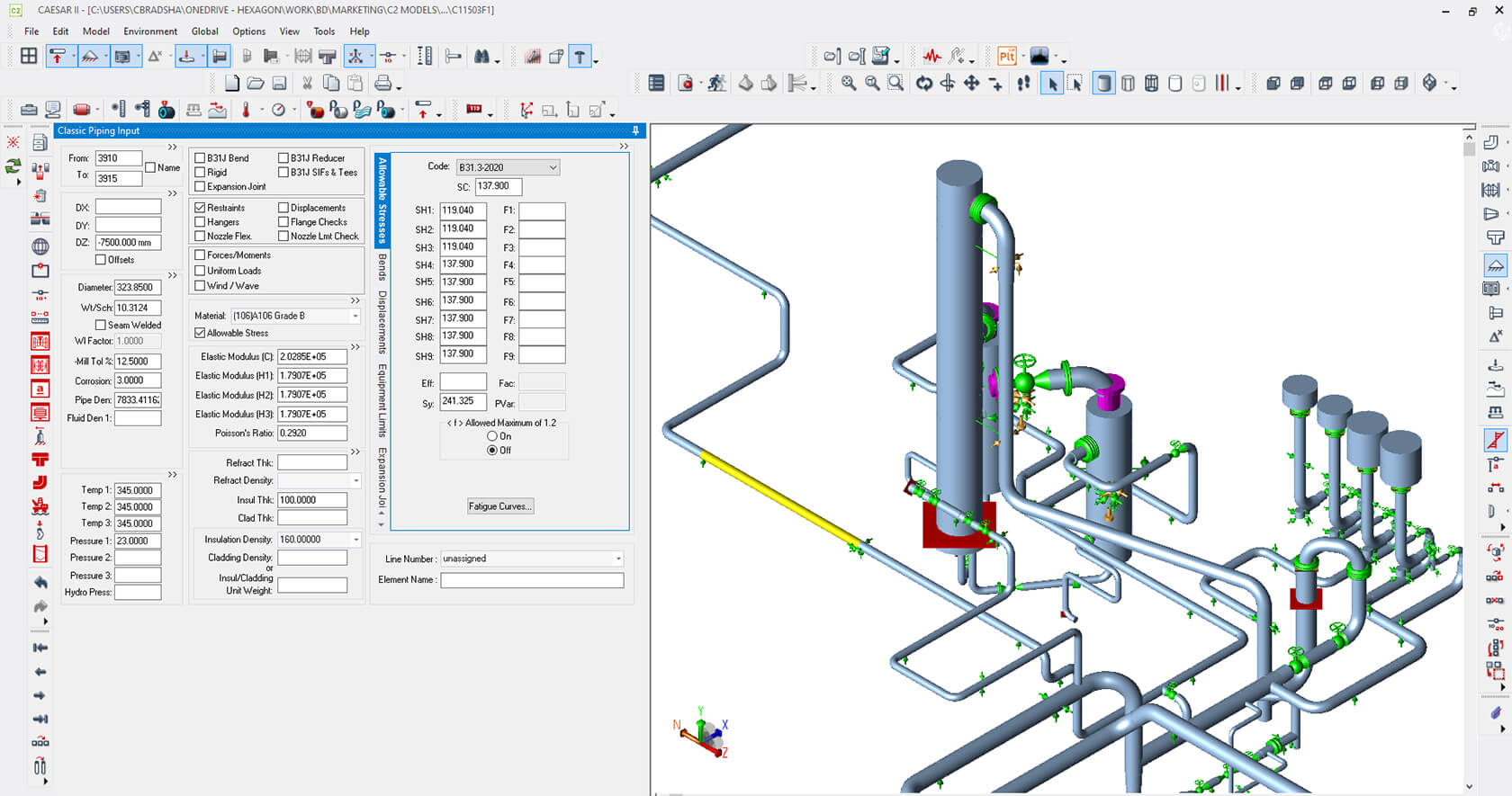

CAESAR II is a software package for piping flexibility analysis with automated code compliance checks. It is easy to use and includes several advanced modules for specialized problems. CAESAR II can nowadays be seen as the “bread and butter” of any pipe stress engineer. This course is not only useful for beginning stress engineers but can also provide valuable knowledge for those who need to be able to interpret pipe stress results such as supervisors and technicians. The aim of our course is therefore not only to become familiar with the basic use of CAESAR II but also to create an engineering understanding of the stress results.

Well this ocurse is for you, where you are going to learn how to model and analyse simple and complex piping systems easily and correctly. Piping stress analysis through examples would be carried out according to international standards such as ASME B.1.3.

Many piping professionals at the beginning of their career get to model piping systems without considering good practices and the theory behind a proper design of a piping system and its piping supports. As a result, non-allowable deflections and overstress take place in the 3D piping model and therefore, a change of the support allocation or the piping route would be neccesary afterwards. This increases the costs and the timeline of the project, which affects its financial feasibility and the client satisfaction.

Get an insight into the world of piping stress analysis with the use of the software Caesar II. Practical examples of the international piping code ASME B31.3 will be exposed and analysed. The results of the analysis with Caesar II and of the piping code B31.3 will be compared to each other such as, forces, displacements, bending and torisonal stress and stress ratio.

DESCRIPTION

CAESAR II is a software package for piping flexibility analysis with automated code compliance checks. It is easy to use and includes several advanced modules for specialized problems. CAESAR II can nowadays be seen as the “bread and butter” of any pipe stress engineer. This course is not only useful for beginning stress engineers but can also provide valuable knowledge for those who need to be able to interpret pipe stress results such as supervisors and technicians. The aim of our course is therefore not only to become familiar with the basic use of CAESAR II but also to create an engineering understanding of the stress results.

Well this ocurse is for you, where you are going to learn how to model and analyse simple and complex piping systems easily and correctly. Piping stress analysis through examples would be carried out according to international standards such as ASME B.1.3.

Many piping professionals at the beginning of their career get to model piping systems without considering good practices and the theory behind a proper design of a piping system and its piping supports. As a result, non-allowable deflections and overstress take place in the 3D piping model and therefore, a change of the support allocation or the piping route would be neccesary afterwards. This increases the costs and the timeline of the project, which affects its financial feasibility and the client satisfaction.

Get an insight into the world of piping stress analysis with the use of the software Caesar II. Practical examples of the international piping code ASME B31.3 will be exposed and analysed. The results of the analysis with Caesar II and of the piping code B31.3 will be compared to each other such as, forces, displacements, bending and torisonal stress and stress ratio.

Who should join Training PVElite by Oil Institut?

This course will specifically benefit :

Piping Engineer

Mechanical Engineering

Piping Designer

COURSE CONTENT STATIC ANALYSIS

Theory and Development of Pipe Stress Requirements

Introduction to the features and functions of Caesar II

Modeling and input routing of pipes, equipment in various design conditions: thermal, displacement, wind load, seismic, PSV, Flange leakage, Flexibility Nozzle, etc

Creating Load Cases: Hydrotest, Operating, Sustain, Expansion, Occasional

Read and understand Output: stress summary, restraint summary, displacement, flange leakage, etc

Study the output and its correlation to Code and Standard: WRC 107/297, API 610, API 661, API 617, NEMA SM23

Solving problems in pipe routing: modification of support, modification of routing, using piping components as problem solving, such as Spring Support, Expansion Joint

Create Piping Stress Analysis documents, as reports and information

DURATION COURSE:

2 days

@8 hour / day

SCHEDULE COURSE 2026

January

February

March

April

Mei

June

July

August

September

October

November

December

*Start the course the first week of every month